Mass-Minimized Load-Bearing Part & Four-Bar Linkage

Carnegie Mellon University Course Project

Fall 2023 24-261 Mechanics 1: 2D Design

Made in partnership with Teresa Cai and Sarah Wang

As part of my course in Mechanics 1: 2D Design for my Mechanical Engineering education, we were placed into groups of three and tasked with two projects: Making a Four-Bar acrylic linkage that could be cranked on one bar to generate a unique coupler curve that could be used as a miniature golf-course obstacle and to use Finite Element Analysis to create a mass-minimized acrylic part that would hold know weights without failing.

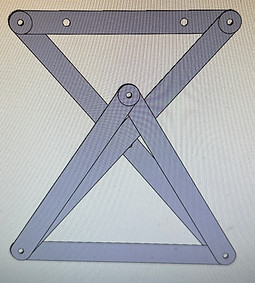

For the four-bar linkage, my teammates and I discussed our designs and collaborated to create a group design that would generate a coupler curve similar to Figure 8. This movement of the linkage created a fun-looking twisting motion that we interpreted as an angry goose trying to block the ball. First, we designed our final linkage in Motiongen and Solidworks, then we sent it to the course TAs for cutting. We then printed out some simple designs for the goose and stuck it to the linkage to demonstrate our coupler curve.

For the mass-minimized part, we similarly made our designs and then collaborated to create a design for the group. Since the design of the part was constrained to the types of supports available to the loading rig and the distance from the supports, we started by constraining our design to what we believed was the optimal positioning. In our first iteration, we found a substantial benefit to our L-shape design as well as the thickness and length we assigned it. In our second iteration, we continuously removed mass from the middle and outside of the part while constantly checking its factor of safety. Eventually, we found ourselves at a weight of 2.9 grams with a factor of safety of 1.2 and were able to hold 50 pounds total. While we were the 4th lightest part in the class we were the first to log a weight under 3 grams.